19

2025

-

02

ວິທີໃຊ້ເພື່ອປັບປຸງຄຸນນະພາບຂອງບັດບັດສໍາລັບສິນຄ້າໄຟຟ້າໃນດອງກວານ?

ເອົາ:

ໃນຕະຫຼາດສິນຄ້າເຄື່ອງດິຈິຕອນທີ່ແຂ່ງກັນສູງໃນມື້ນີ້, ຄຸນນະສົມບັດຂອງບັດສິນຄ້າບໍ່ແຕ່ສົງສິດສະທໍາສະດວກສຳລັບຄວາມປອດໄພຂອງສິນຄ້າ.

How to improve the quality of blister packaging for electronic products in Dongguan?

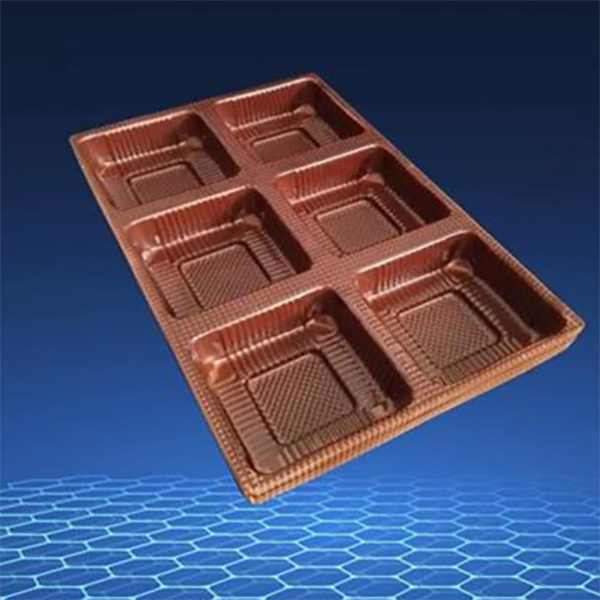

In today's highly competitive electronic product market, the quality of product packaging not only directly affects the safety of the product but also relates to the brand image and consumer purchasing experience. Especially in Dongguan, a hub for electronic product manufacturing, how to enhance the quality of disposable blister packaging has become a focus for many companies. So, what should be done? Next, let's explore some effective strategies to improve the quality of blister packaging.

1. Material selection is crucial

First, choosing the right materials is the first step to improving the quality of blister packaging. High-quality plastic materials can not only protect electronic products from damage during transportation but also effectively resist moisture and dust. For example, using polystyrene (PS) or polypropylene (PP) materials, which not only have good transparency but also ensure the sturdiness of the packaging.

Moreover, the environmental friendliness of materials is increasingly being noticed by consumers. Choosing materials that meet environmental standards can reduce the impact on the environment and enhance the brand image, making it a win-win strategy.

2. Design a reasonable structure

Secondly, structural design also has a direct impact on the quality of blister packaging. A reasonable structural design can effectively secure the product, preventing displacement and collision, while also enhancing the aesthetic appeal of the product visually. When designing, consider using a multi-layered blister structure to add depth to the product while also enhancing protective effectiveness.

For example, in the packaging of some high-end electronic products, a layered design can be used to separate the accessories from the main unit, which not only reduces the chance of scratches but also provides a better experience for consumers when unpacking.

3. Precise production process

Furthermore, a precise production process is also an important aspect of improving the quality of disposable blister packaging in Dongguan. The production process of blister packaging involves multiple steps such as thermoforming, cutting, and punching, each of which needs to be strictly controlled.

Therefore, companies should invest in high-end production equipment and regularly maintain and update it. At the same time, the technological level of the production team should not be overlooked; regular training and skill enhancement will directly affect the final quality of the product.

4. Strict quality inspection

Of course, quality inspection is a necessary part of ensuring packaging quality. Conducting strict quality inspections before products leave the factory can timely identify potential issues and prevent substandard products from entering the market. Inspection content can include material pressure resistance, transparency, structural integrity, and more.

Imagine if an electronic product is damaged during transportation due to substandard packaging quality, the disappointment of consumers will directly affect the brand's reputation. Therefore, companies should pay attention to every inspection link to ensure the safety and reliability of the products.

5. Continuous innovation and feedback

Finally, companies should maintain keen market insights and engage in continuous innovation. As consumer demands change, packaging design also needs to be updated continuously. For example, more and more consumers hope to see more environmentally friendly and smarter packaging solutions. Companies can adjust their product packaging strategies in a timely manner through market research and consumer feedback, thereby improving the overall quality of blister packaging.

In this rapidly changing market, maintaining flexibility and innovation capability is key for companies to remain competitive.

Summary

In summary, improving the quality of disposable blister packaging for electronic products in Dongguan is a systematic project that involves material selection, structural design, production processes, quality inspection, and innovation feedback. By implementing the above measures, companies can not only enhance the market competitiveness of their products but also establish a good brand image in the minds of consumers.

In this fast-developing era, let us work together to improve the quality of blister packaging for electronic products in Dongguan!

ການສະແດງສະຖານທີ່ສິບປີຂອງຈິງດິງເປັນຄວາມສຳເລັດສົດໃໝ່!

ເວລາໄຫລ່ດັ່ງເພງ, 20 ປີຂອງການປູກປິ່ນ; ສະດວກວັນເກິດຮ່ວມກັນ, ສ້າງອະນາຄົດທີ່ດີກວ່າ.

2025-02-19

ການປັບປຸງການຄອດປະກອບສິນຄ້າ: ຂໍໍ່ທີ່ດີຂອງການບັດບັດສິນຄ້າດິງກວານ ດິງກວານ ອິເລັກທຣິກ ພາກກະທົບສິນຄ້າ

ໃນສະຖານທີ່ທຸລະກິດສະໃໝ່, ຄວາມປອດໄພ ແລະ ຄວາມສົມບູນຂອງສິນຄ້າແມ່ນສິ່ງສຳຄັນ.

2025-02-19